Looking for the "Aspen Gold" Spray Paint [Column_Parts & Materials]

: examples and color tips

: examples and color tipsAs I have neither spray guns nor paint booth, I owe my paint works to spray paints from the hobby market. I collected of-a-kind yellow color spray paints from the market in Japan. Here is the result. I decided to use the one, shown at the top of the right row in the picture above, TAMIYA TS-56, "BRILLIANT ORANGE". Sounds brilliant!

Left row from the top;

INTERMOUNTAIN F7, #69211-03.

Atlas GP30, #42816,

Trainworx caboose,

Atlas wide-vision caboose, #30611,

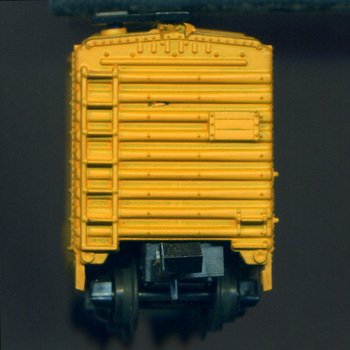

Athern boxcar, #14159,

MicroTrains boxcar, #32220,

MicroTrains boxcar, #37030

筆者は模型の塗装を市販のスプレー塗料に頼っている。Rio Grandeの模型を塗装するにあたって、日本で売っているものの中に使えるものはないかと探してみた。その結果が上の写真である。実物との比較のしようがないので、手持ちの塗装済み完成品模型と比較してみた。自然光のみで撮ってはいるが、あくまでも本画像内での比較にとどめておかれたい。

左列は上から

INTERMOUNTAINのF7, #69211-03、

AtlasのGP30, #42816、

先出の自作caboose、

Atlasのcaboose, #30611、

Athernのboxcar, #14159、

MicroTrainsのboxcar, #32220、

MicroTrainsのboxcar, #37030

である。MSCGやその他の資料で見比べても色の印象は異なるし、元々異なる色である場合もある。例えば1984年に増備された中古のGP40は、より赤みの強いオレンジ色に塗られている。古いAtlas/Kato製機関車の塗色はこちらに近いように感じられる。また面積によっても色の印象は変わることはご存じであろう。

右列は上から

タミヤカラー・ミニのTS-56、ブリリアントオレンジ(つやあり)/グリーンマックス・鉄道カラーの#39、アルミシルバー(光沢表記なし)

グリーンマックス・鉄道カラーの#17、近鉄オレンジ(光沢表記なし)

Mr.COLORの#109、キャラクターイエロー(半光沢)

Mr.COLORの#58、黄橙色(半光沢)

タミヤカラー・ミニのTS-34、キャメルイエロー(つやあり)

タミヤカラー・ミニのTS-30、シルバーリーフ(つやあり)

タミヤカラー・ミニのTS-76、マイカシルバー(つやあり)

である。いずれも白色プラ板に直接2回吹いている。

筆者は黄色については、デカールの仕上がりを鑑み、つやありの中からRio Grandeの地元・コロラド州にある模型店・N SCALE SUPPLYが"correct color"だという特製デカール(#NSS-60-28)に最も近い色と思われる、タミヤのTS-56を選んだ。

特製デカールについては;

http://www.nscalesupply.com/MSD/NSS-60-28.html

銀色については、顔料のきめの細かさでグリーンマックスの#39を選んだ。

USM Haller System 01 [Column_Parts & Materials]

: USM Haller showcase

: USM Haller showcaseWhat kind of showcase do you use to display your collection?

I'm using the USM Haller System made in Swiss. This system has consisted of joints, pipes and side-panels or doors. The joints and pipes are chrome plated. Both steel and glass are prepared for the panel or the door. As a modular system, you can extend widths, depths or heights. Attachments like drawers and lights are also provided.

Watching one's own collection maybe a joyful time for the enthusiasts who don't have a layout.

Actually, the amount of the case is bigger than the amount of its contents except the books.

筆者はレイアウトをもっていないので、模型をガラスケースに並べて楽しんでいる。

使っているのはUSM・ハラーという家具である。おおよそ3750w/350d/750hある。大きさにもよるだろうが、家具屋に同程度の大きさの木製陳列ケースを特注するより若干安くできるように思う。システムになっていて、ガラス/金属パネルはもちろん、縦横高さどちらにも拡張可能になっている。引き出しや照明を組み込むこともできる。日焼けが気になる方にはUVカットフィルムをガラスに貼ってくれる。機能・デザインともよくできたシステムである。

コレクションを一望に眺めニヤニヤする時間は、とても楽しい時間である。特注するより若干安いのは事実だが、ブラスモデルならともかく筆者が現時点で中身に費やした金額よりケースの方が高いのも事実である。

導入したのは、趣味とその他を空間的になじませようと思ったからである。余人にとっては子供のオモチャにしか見えないであろうものたちが大人の空間にあふれている様に対する違和感が、高級そうに見えるケースに入れることで、多少減衰するように思う。

USM・ハラーを紹介するページ;

https://www.usm.com

USM Haller System 02 [Column_Parts & Materials]

: detail of the showcase

: detail of the showcaseThe Haller System doesn't have inside racks. So I designed and made it from clear acrylic plate.

As a result, one module (w750, d250, h350mm) of my case holds 60 50feet N scale boxcars. Maybe I should apply UV-cut sheet on the glass.

My friend who saw my collection told me he first thought that they are chocolates. It is indeed a kind of favorites though.

USM・ハラーシステムには内に仕切り棚がない。筆者は3ミリのアクリル板で外注した。ひな壇状のデザインの方が、奥までよく見えるし強度も出るのだろうが、高くつきそうなので単に平らなデザインにした。9ミリ間隔の溝を彫って模型がきちんと並ぶようにしてみた。1段にNスケールで50フィートの貨車が30両並ぶ。板厚3ミリで、30両分の重量には十分だったが、機関車には貫が少し薄かったようで、ほんの少し垂れてきた。

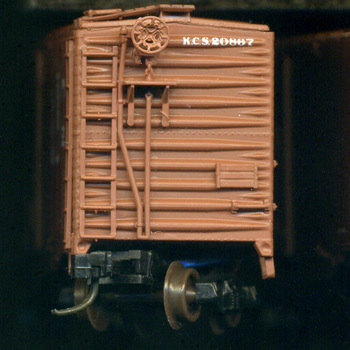

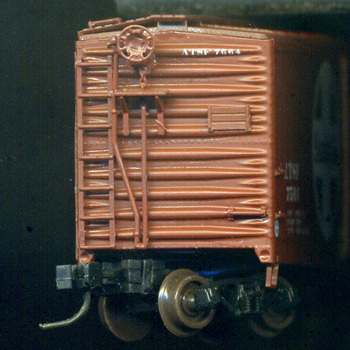

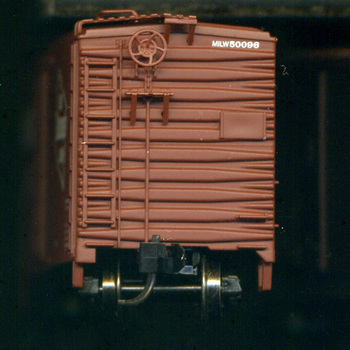

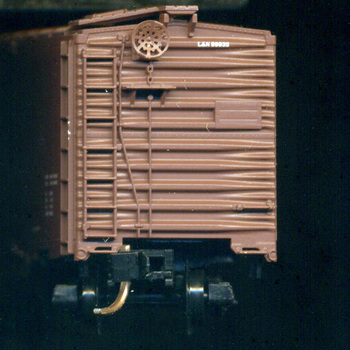

このブログの名称にあるように、筆者の収集の対象は茶色い貨車である。先日(2月)このケースを見たわたしの友人は「チョコレートかと思たで」と宣うた。ケースに入れたことの効能が現れたのか判断し難いが、わたしにとってはまぁ似たようなものである。

Under frame components 01 [Column_Parts & Materials]

: propane fuel carriers maybe made by Waukesha installed on SOU 25

: propane fuel carriers maybe made by Waukesha installed on SOU 25I bought a passenger car roof and underframe accessories set by American Limited Models to detail Rio Grande dynamometer car produced by MTL.

As I have little Knowledge of passenger car underframe components, the instruction has a lot of information for me. There, several air-conditioning system manufacturers are mentioned; Waukesha, Frigidaire and SCH&L.

In 1906, Harry Horning, and Frederick Ahern established the garage repairing and storing cars in Waukesha, Wisconsin. In 1935, then the Waukesha Motor Company began producing ice engines for railway equipment. The company was finally acquired by Dresser and became Dresser Waukesha in 1974. Today the company mainly produces gensets.

Dresser Waukesha homepage;

In 1916, Alfred Mellowes and others formed the Guardian Refrigerator Company in Fort Wayne, Indiana. In 1918, General Motors Corp. president, William C. Durant acquired Guardian and renamed the company and its products "Frigidaire." Today, the company produces kitchen and laundry machinery, air conditioners, and dehumidifiers.

Frigidaire homepage;

In conjunction with George M. Pullman and others, Arthur W. Soper organized the Safety Car Heating & Lighting Co. in 1887. The company produced pintsch gas equipment, heating equipment, electric lighting equipment lighted buoys and vapor lights. Not only equipment but the company also provided pintsch gas to the railroads using pintsch gas lighting for the passenger cars in its early days.

Article mentioning SCH&L found on google books;

I wonder who produced the system using steam to evaporate which I took the photo at Calgary, Canada in 1971.

CP Rail's "The Canadian" using steam for air conditioning;

Under frame components 02 [Column_Parts & Materials]

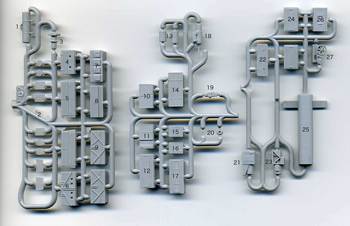

: Passenger Car Roof and Underframe Accessories by American Limited Models

: Passenger Car Roof and Underframe Accessories by American Limited ModelsThis set consists of a water tank, brake equipment, generator, battery boxes, air conditioning systems, and roof details.

The air conditioning equipment by WAUKESHA is 7, 8, 11, 16, and 21. The equipment by FRIGIDAIRE is 12, 17, 26 and 27. The equipment by SAFETY CAR HEATING & LIGHTING is 10, 14, 23.

According to the MSCG to the Rio Grande, the prototype had engine and generator. But it is not written that they were installed under the floor. An exhaust pipe on the roof and the windows plated with horizontal louvers suggest that the genset was installed in the room. MSCG lacks comment on the air conditioner. Maybe it lacked air conditioning.

I can see a water tank like equipment in the picture of the prototype. But, it is not set in the center of the car. Maybe it is not a water tank considering the weight balance.

Here is the conclusion that I have no parts to use on detailing the Rio Grande 10.

Under frame components 03 [Column_Parts & Materials]

: Hase, Hyogo, Japan. Jan. 8, 1995

: Hase, Hyogo, Japan. Jan. 8, 1995I, somewhere and once, saw a photo, viewing the head end of a train tracing the curve, from the space between the rail and the under frame of its pulling consists. I was fascinated with that photo.

I wanted to take my own, but found it quite difficult; I needed a tight curve, a train to some extent, consists with light under frame components to allow the space to view the head end.

Here, in Japan, we have few straight side freight cars (almost all replaced by COFC flats with fishbelly side). We have few passenger cars with light under frame components (almost all replaced by RDCs and M.U. electric cars). We have few long trains with diesel engines on head end (trains shortened and electrified).

The photo above is my only photo succeeded in catching the engine looking through the under frame of the passenger car. Though it thought to be the last chance for such a kind of photo, I only found that I needed longer train and lens after the train passed away.

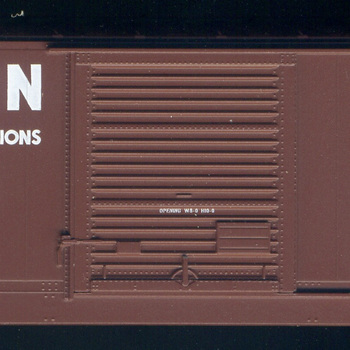

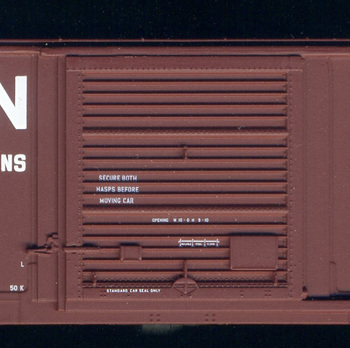

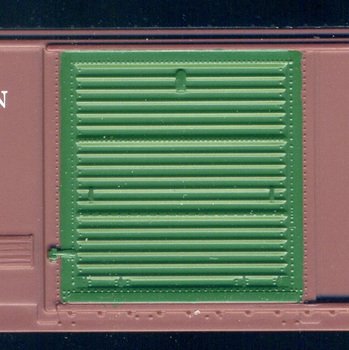

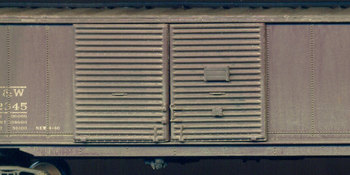

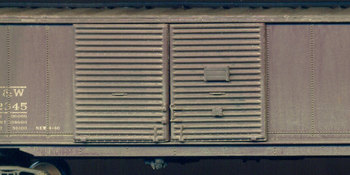

N scale Sliding Doors – Youngstown 01 [Column_Parts & Materials]

: Feb 11, 1998. Osaka, Japan

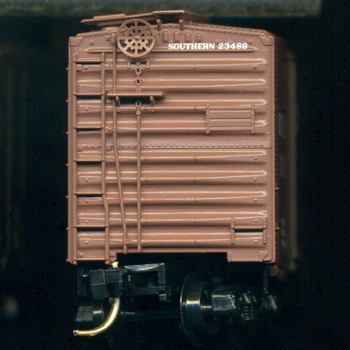

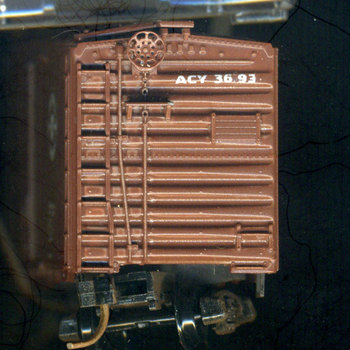

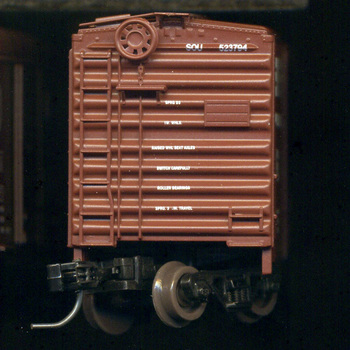

: Feb 11, 1998. Osaka, JapanThe characteristics of the door might be one of the key elements in boxcar design. The arrangement, dimensions and function of door would govern the value of the equipment. From the hobbyist’s point of view, the variation encourages our incentive to kit bashing or scratch building a particular model.

In N scale, we have little choice on replacing doors. I believe we need more door parts. For the present, I found these doors in my collection. Pics and dimensions would help your kit bashing.

I’ll begin with the monolithic molded “Youngstown” doors.

Youngstown Steel Door Company was founded in 1924 and was based in its namesake town Youngstown, OH. The company now forms the Greenbrier Companies with the name YSD Industries.

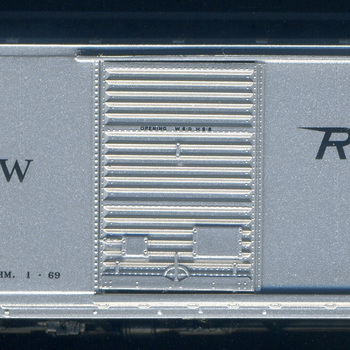

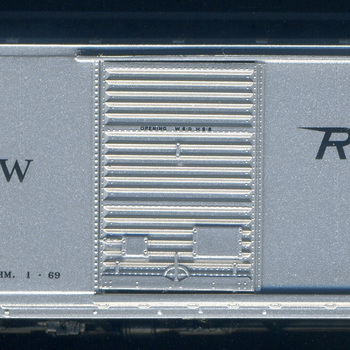

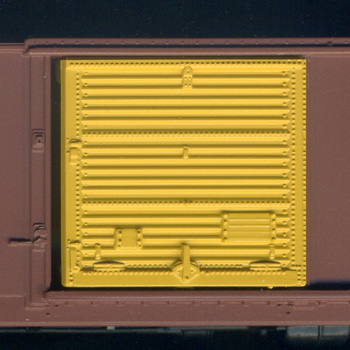

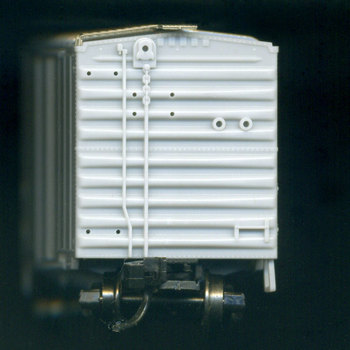

N scale Youngstown Doors, Monolithic Mold (available only as bodies)

Dimensions are described in millimeter on N scale model/in foot on converted actual size.

9’ single door

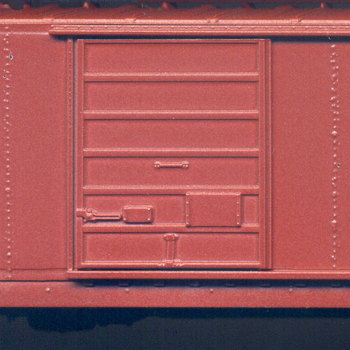

: Athearn 50’ PS-1 Single door Boxcar door

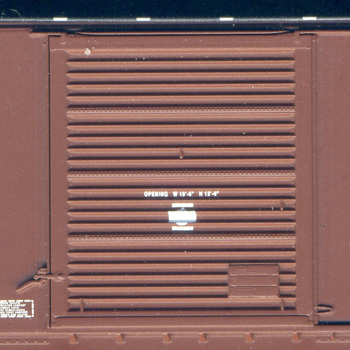

: Athearn 50’ PS-1 Single door Boxcar doorThis 5/6/6 corrugated sliding door is found on Athearn 50’ PS-1 Single door Boxcar. Dimensions are: 17.6mmW-19.2mmH/9’3”W-10’1”H

10’ single door

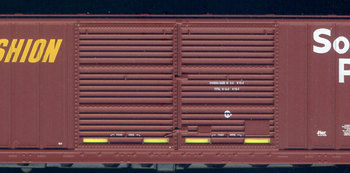

: Atlas 50' ACF

: Atlas 50' ACFThis 5/6/6 corrugated sliding door is found on Atlas 50' ACF

: Athearn 50' FMC Single Door Boxcar door

: Athearn 50' FMC Single Door Boxcar doorThis 6/6/6 corrugated sliding door is found on Athearn 50' FMC Single Door Boxcar. It lacks tack board: it’s on the left side of the door. Dimensions are: 19.3mmW-20.1mmH/10’1”W-10’6”H

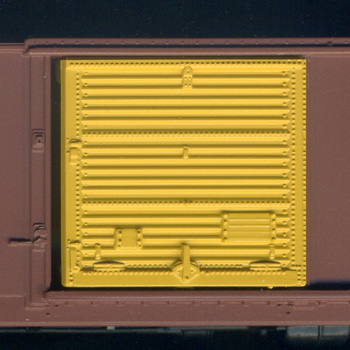

: Exactrail PC&F 6033 cu. ft. Hi-Cube Boxcar door

: Exactrail PC&F 6033 cu. ft. Hi-Cube Boxcar doorThis 5/5/5/6 corrugated sliding door is found on Exactrail PC&F 6033 cu. ft. Hi-Cube Boxcar. Dimensions are: 21.0mmW-23.3mmH/11’ W-12’3”H

7.5’+7.5’ double door

: Atlas Trainman 50' Double Door Boxcar doors

: Atlas Trainman 50' Double Door Boxcar doorsThis corrugated sliding doors are found on Atlas Trainman 50' Double Door Boxcar. Dimensions are: 27.9mmW-16.5mmH/14’8”W-8’8”H

7’+8’ double door

: Athearn 50' PS1 Double Door Boxcar doors

: Athearn 50' PS1 Double Door Boxcar doorsThis 5/6/6 corrugated sliding doors are found on Athearn 50' PS1 Double Door Boxcar. Dimensions are: 30.2mmW-19.3mmH/15’10”W-10’1”H

8’+8’ double door

: FVM FMC 5283 cu. ft. Double Door Boxcar doors

: FVM FMC 5283 cu. ft. Double Door Boxcar doorsThis 6/6/6 corrugated sliding doors are found on FVM FMC 5283 cu. ft. Double Door Boxcar. It features second latch for the security device. Dimensions are: 32.5mmW-20.1mmH/17’ W-10’6”H

: Exactrail Gunderson 5200 Boxcar doors

: Exactrail Gunderson 5200 Boxcar doorsThis 6/6/6 corrugated sliding doors are found on Exactrail Gunderson 5200 Boxcar. Incorporate fork pockets are featured in the lower corrugation. Dimensions are: 32.0mmW-20.0mmH/16’9”W-10’6”H

2012-10-12 09:00

コメント(0)

N scale Sliding Doors – Youngstown 02 [Column_Parts & Materials]

Here are the Youngstown doors available in separate parts. It is much easier to transplant, but hard to get except some MTL parts.

N scale Youngstown Doors, Separate Parts (available as parts)

Dimensions are described in millimeter on N scale model/in foot on converted actual size.

6’ single door

: MTL 40' Std Single Door Boxcar door

: MTL 40' Std Single Door Boxcar door

This 5/6/6 corrugated sliding door is found on MTL 40' Std Single Door Boxcar. The door is sold as #499 20 935 6’ Youngstown Doors (For 40’ Cars). Dimensions are: 12.4mmW-18.3mmH/6’6”W-9’7”H

: Intermountain 12 Panel 40’ Boxcar door

: Intermountain 12 Panel 40’ Boxcar door

This 4/6/6 corrugated sliding door is found on Intermountain 12 Panel 40’ Boxcar. Dimensions are: 11.5mmW-18.0mmH/6’W-9’5”H

: Intermountain Modified AAR 40' Boxcar door

: Intermountain Modified AAR 40' Boxcar door

This 5/6/5 corrugated sliding door is found on Intermountain Modified AAR 40' Boxcar. Dimensions are: 12.0mmW-19.1mmH/6’3”W-10’H

8’ combination door

: MTL 50' Std Boxcar with Plug & Sliding Door

: MTL 50' Std Boxcar with Plug & Sliding Door

This 5/6/6 corrugated sliding door is found on MTL 50' Std Boxcar with Plug & Sliding Door. It resembles the MTL 8’ single door shown below, but rivets are represented on the bottom frame of the door. Dimensions of the sliding door are: 14.9mmW-18.0mmH/7’10”W-9’5”H

8’ single door

: MTL 50' Std Single Door Boxcar door

: MTL 50' Std Single Door Boxcar door

This 5/6/6 corrugated sliding door is found on MTL 50' Std Single Door Boxcar. The door is sold as #499 20 937 8’ Youngstown Doors (for 50’ Cars). Dimensions are: 14.4mmW-18.3mmH/7’6”W-9’7”H

: Intermountain 50' AAR Single Door Boxcar door

: Intermountain 50' AAR Single Door Boxcar door

This corrugated sliding door is found on Intermountain 50' AAR Single Door Boxcar. Dimensions are: 15.2mmW-18.6mmH/7’11”W-9’9”H

: Atlas Master PS-1 40’ Boxcar

: Atlas Master PS-1 40’ Boxcar

This 5/6/6 corrugated sliding door is found on Atlas master PS-1 40’ Boxcar.

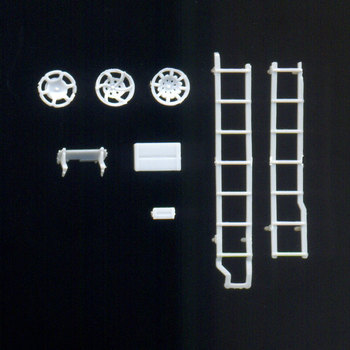

Undecorated car has Pullman, 7 panel and 6 panel Superior doors along with it. Miner, Universal and Ajax brake wheels, ladders, brake platform and tack boards are included as separate parts.

10’ single door

: MTL 50' Rib Side Boxcar door

: MTL 50' Rib Side Boxcar door

This 6/6/6 corrugated sliding door is found on MTL 50' Rib Side Boxcar. It features incorporate fork pockets and second latch for the security device. The door is sold as #499 20 942 10’ Youngstown Doors (For 50' Cars). Dimensions are: 19.2mmW-18.1mmH/7’6”W-9’7”H

7.5’+7.5’ double door

: MTL 40' or 50' Std Double Door Boxcar doors

: MTL 40' or 50' Std Double Door Boxcar doors

This 5/6/6 corrugated sliding doors are found on MTL 40' or 50' Std Double Door Boxcar. The doors are sold as #499 20 940 8’ Youngstown L & R Doors. Dimensions are: 29.0mmW-18.3mmH/15’3”W-9’7”H

: MTL 50' Auto Boxcar doors

: MTL 50' Auto Boxcar doors

This corrugated sliding doors are found on MTL 50' Auto Boxcar. Dimensions are: 31.3mmW-18.8mmH/16’5”W-9’10”H

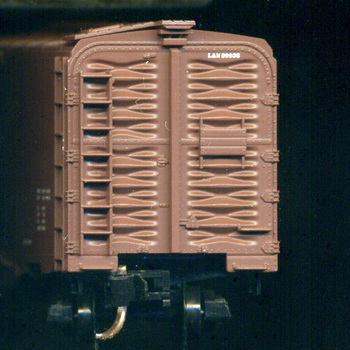

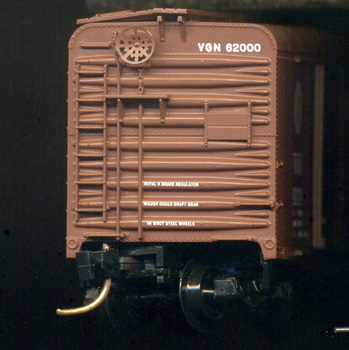

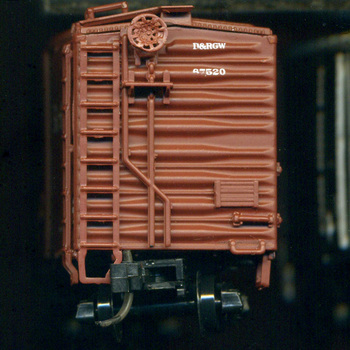

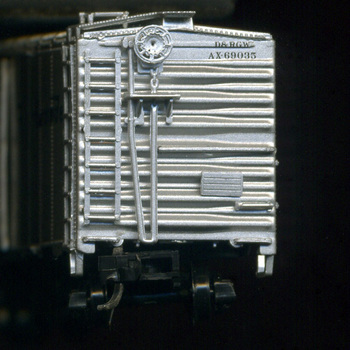

: MTL 50' Wagon Top Boxcar doors

: MTL 50' Wagon Top Boxcar doors

This 5/5/6 corrugated sliding doors are found on MTL 50' Wagon Top Boxcar. Dimensions are: 29.5mmW-17.1mmH/15’6”W-9’H

: Intermountain 50' AAR Standard Double Door Boxcar doors

: Intermountain 50' AAR Standard Double Door Boxcar doors

This corrugated sliding doors are found on Intermountain 50' AAR Standard Double Door Boxcar. Dimensions are: 30.9mmW-18.9mmH/16’2”W-9’11”H

Additional Note

Atlas 1932 ARA Box Car has separate 6’ Youngstown door.

Atlas 60’ Auto Parts Box Car has separate 8’+8’ Youngstown doors.

Atlas Steel Rebuilt Box Car has separate 6’ Youngstown door.

Atlas Trainman 40’ Double Door Box Car has 7.5’+7.5’ Youngstown doors.

Atlas Trainman 50’ Single Door Box Car has 9’ Youngstown door.

Atlas Trainman 50’6” Single Door Box Car has 10’ Youngstown door.

Micro-Trains 60’ Excess Height Single Door Box Car has separate 10’ Youngstown door.

Micro-Trains 40’ USRA Steel Single Door Box Car has separate 6’ Youngstown door.

Inter Mountain 1937 AAR 40’ Box Car has separate 6’ Youngstown door.

Fox Valley FMC 5347 Cuft Single Door Box Car has 10’ Youngstown door.

Fox Valley FMC PS 5344 Cuft Single Door Box Car has 10’ Youngstown door.

Fox Valley B&O Wagontop Box Car has 6’ Youngstown door.

Deluxe Innovations 1944 AAR Box Car has separate 6’ Youngstown door.

N scale Youngstown Doors, Separate Parts (available as parts)

Dimensions are described in millimeter on N scale model/in foot on converted actual size.

6’ single door

: MTL 40' Std Single Door Boxcar door

: MTL 40' Std Single Door Boxcar doorThis 5/6/6 corrugated sliding door is found on MTL 40' Std Single Door Boxcar. The door is sold as #499 20 935 6’ Youngstown Doors (For 40’ Cars). Dimensions are: 12.4mmW-18.3mmH/6’6”W-9’7”H

: Intermountain 12 Panel 40’ Boxcar door

: Intermountain 12 Panel 40’ Boxcar doorThis 4/6/6 corrugated sliding door is found on Intermountain 12 Panel 40’ Boxcar. Dimensions are: 11.5mmW-18.0mmH/6’W-9’5”H

: Intermountain Modified AAR 40' Boxcar door

: Intermountain Modified AAR 40' Boxcar doorThis 5/6/5 corrugated sliding door is found on Intermountain Modified AAR 40' Boxcar. Dimensions are: 12.0mmW-19.1mmH/6’3”W-10’H

8’ combination door

: MTL 50' Std Boxcar with Plug & Sliding Door

: MTL 50' Std Boxcar with Plug & Sliding DoorThis 5/6/6 corrugated sliding door is found on MTL 50' Std Boxcar with Plug & Sliding Door. It resembles the MTL 8’ single door shown below, but rivets are represented on the bottom frame of the door. Dimensions of the sliding door are: 14.9mmW-18.0mmH/7’10”W-9’5”H

8’ single door

: MTL 50' Std Single Door Boxcar door

: MTL 50' Std Single Door Boxcar doorThis 5/6/6 corrugated sliding door is found on MTL 50' Std Single Door Boxcar. The door is sold as #499 20 937 8’ Youngstown Doors (for 50’ Cars). Dimensions are: 14.4mmW-18.3mmH/7’6”W-9’7”H

: Intermountain 50' AAR Single Door Boxcar door

: Intermountain 50' AAR Single Door Boxcar doorThis corrugated sliding door is found on Intermountain 50' AAR Single Door Boxcar. Dimensions are: 15.2mmW-18.6mmH/7’11”W-9’9”H

: Atlas Master PS-1 40’ Boxcar

: Atlas Master PS-1 40’ BoxcarThis 5/6/6 corrugated sliding door is found on Atlas master PS-1 40’ Boxcar.

Undecorated car has Pullman, 7 panel and 6 panel Superior doors along with it. Miner, Universal and Ajax brake wheels, ladders, brake platform and tack boards are included as separate parts.

revised, Mar 25, 2015

10’ single door

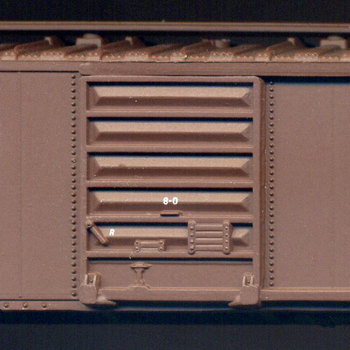

: MTL 50' Rib Side Boxcar door

: MTL 50' Rib Side Boxcar doorThis 6/6/6 corrugated sliding door is found on MTL 50' Rib Side Boxcar. It features incorporate fork pockets and second latch for the security device. The door is sold as #499 20 942 10’ Youngstown Doors (For 50' Cars). Dimensions are: 19.2mmW-18.1mmH/7’6”W-9’7”H

7.5’+7.5’ double door

: MTL 40' or 50' Std Double Door Boxcar doors

: MTL 40' or 50' Std Double Door Boxcar doorsThis 5/6/6 corrugated sliding doors are found on MTL 40' or 50' Std Double Door Boxcar. The doors are sold as #499 20 940 8’ Youngstown L & R Doors. Dimensions are: 29.0mmW-18.3mmH/15’3”W-9’7”H

: MTL 50' Auto Boxcar doors

: MTL 50' Auto Boxcar doorsThis corrugated sliding doors are found on MTL 50' Auto Boxcar. Dimensions are: 31.3mmW-18.8mmH/16’5”W-9’10”H

: MTL 50' Wagon Top Boxcar doors

: MTL 50' Wagon Top Boxcar doorsThis 5/5/6 corrugated sliding doors are found on MTL 50' Wagon Top Boxcar. Dimensions are: 29.5mmW-17.1mmH/15’6”W-9’H

: Intermountain 50' AAR Standard Double Door Boxcar doors

: Intermountain 50' AAR Standard Double Door Boxcar doorsThis corrugated sliding doors are found on Intermountain 50' AAR Standard Double Door Boxcar. Dimensions are: 30.9mmW-18.9mmH/16’2”W-9’11”H

Additional Note

Atlas 1932 ARA Box Car has separate 6’ Youngstown door.

Atlas 60’ Auto Parts Box Car has separate 8’+8’ Youngstown doors.

Atlas Steel Rebuilt Box Car has separate 6’ Youngstown door.

Atlas Trainman 40’ Double Door Box Car has 7.5’+7.5’ Youngstown doors.

Atlas Trainman 50’ Single Door Box Car has 9’ Youngstown door.

Atlas Trainman 50’6” Single Door Box Car has 10’ Youngstown door.

Micro-Trains 60’ Excess Height Single Door Box Car has separate 10’ Youngstown door.

Micro-Trains 40’ USRA Steel Single Door Box Car has separate 6’ Youngstown door.

Inter Mountain 1937 AAR 40’ Box Car has separate 6’ Youngstown door.

Fox Valley FMC 5347 Cuft Single Door Box Car has 10’ Youngstown door.

Fox Valley FMC PS 5344 Cuft Single Door Box Car has 10’ Youngstown door.

Fox Valley B&O Wagontop Box Car has 6’ Youngstown door.

Deluxe Innovations 1944 AAR Box Car has separate 6’ Youngstown door.

2012-10-19 09:00

コメント(0)

N scale Sliding Doors – Superiors and Pullmans [Column_Parts & Materials]

: Jul 1, 2002. Osaka, Japan

: Jul 1, 2002. Osaka, JapanNext are the doors by Superior Car Door Company and Pullman Standard.

Superior Car Door Company was based in Chicago. The company was merged into Chicago Railway Equipment Company, and was later absorbed by Evans Products Company.

Pullman-Standard Car Manufacturing Company was established in 1930 and based in Chicago. The company was absorbed by Bombardier in 1987.

For the present, I found these doors in my collection. Pics and dimensions would help your kit bashing. Dimensions are described in millimeter on N scale model / in foot on converted actual size.

N scale Superior Doors, Separate Parts (available as parts)

6’ Single Door

: MTL 40' Std Single Door Boxcar door

: MTL 40' Std Single Door Boxcar doorThis 7 panel sliding door is found on MTL 40' Std Single Door Boxcar. The door is sold as #499 20 915 6’ Superior Doors (For 40’ Cars). Dimensions are: 12.4mmW-18.3mmH/6’6”W-9’7”H

: Intermountain 1937 AAR 40’ Boxcar door

: Intermountain 1937 AAR 40’ Boxcar doorThis 7 panel sliding door is found on Intermountain 1937 AAR 40’ Boxcar. Dimensions are: 11.8mmW-18.0mmH/6’2”W-9’5”H

8’ Single Door

: MTL 50' Std Single Door Boxcar door

: MTL 50' Std Single Door Boxcar doorThis 6 panel sliding door is found on MTL 50' Std Single Door Boxcar. The door is sold as #499 20 916 8’ Superior Doors (For 50’ Cars). Dimensions are: 15.0mmW-18.5mmH/7’10”W-9’8”H

: Atlas Master PS-1 40’ Boxcar

: Atlas Master PS-1 40’ BoxcarThis 6 panel sliding door is found on Atlas master PS-1 40’ Boxcar.

Undecorated car has Pullman, 7 panel Superior and Youngstown doors along with it. Miner, Universal and Ajax brake wheels, ladders, brake platform and tack boards are included as separate parts.

: Atlas Master PS-1 40’ Boxcar

: Atlas Master PS-1 40’ BoxcarThis 7 panel sliding door is found on Atlas master PS-1 40’ Boxcar.

Undecorated car has Pullman, 6 panel Superior and Youngstown doors along with it. Miner, Universal and Ajax brake wheels, ladders, brake platform and tack boards are included as separate parts.

N scale Pullman Doors, Monolithic Mold (available only as bodies)

8’ Single Door

: Atlas Trainman 40’ PS-1 Boxcar door

: Atlas Trainman 40’ PS-1 Boxcar doorThis 6 panel sliding door is found on Atlas Trainman 40’ PS-1 Boxcar. The embossings added to the panels are exaggeratedly represented on the model. Dimensions are: 14.5mmW-17.2mmH/7’7”W-9’H

N scale Pullman Doors, Separate Parts (available as parts)

8’ Single Door

: Atlas Master PS-1 40’ Boxcar

: Atlas Master PS-1 40’ BoxcarThis 6 panel sliding door is found on Atlas master PS-1 40’ Boxcar.

Undecorated car has 6 panel Superior, 7 panel Superior and Youngstown doors along with it. Miner, Universal and Ajax brake wheels, ladders, brake platform and tack boards are included as separate parts.

10’ Single Door

: Intermountain PS 5277 cu. ft. Boxcar door

: Intermountain PS 5277 cu. ft. Boxcar doorThis embossed sliding door is found on Intermountain PS 5277 cu. ft. Boxcar. It features unlocked latch for the security device. Dimensions are: 19.3mmW-19.7mmH/10’1”W-10’2”H

: MTL 40’ Hi-Cube Boxcar door

: MTL 40’ Hi-Cube Boxcar doorThis embossed sliding door is found on MTL 40’ Hi-Cube Boxcar. Dimensions are: 19.6mmW-23.7mmH/10’3”W-12’5”H

Additional Note

Athearn 50’ Berwick Box Car has 10’ Pullman Door.

Athearn 50’ Sieco Box Car has 10’ Superior-type Door.

Fox Valley Milwaukee Road 50’ Rib Sided Box Car has 6’ Superior-type Door.

Exactrail Evans 5277 Box Car has 10’ Superior-type Door.

Exactrail Evans-USRE Box Car(eary) has 10’ Superior-type Door.

(According to the Freight Cars Illustrated Vol. 9, there are many manufacturers producing boxcar doors resemble Superior. “Superior-type” is my provisional explanation for the time being)

revised, Mar. 25, 2015

2012-10-26 09:00

コメント(0)

Structure of Model Trains [Column_Parts & Materials]

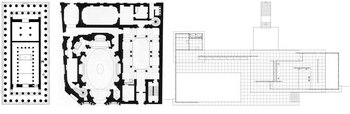

: plans of Greek, baroque and modern architectures

: plans of Greek, baroque and modern architecturesHere, in this column, structure means a fundamental notion referring to recognition of patterns and relations, such as built structure: not a model structure, but a structure of model trains.

In architectural history, the structure of architecture was used to expose. For example, exposed columns surround the walls at Parthenon of 1st century BC. But, columns melt into walls at San Carlo Alle Quattro Fontane, the baroque architecture of 17th century AD. And finally, columns are almost invisible at Barcelona Pavilion, the modern architecture of 20th century AD. Accordingly, the history of architecture can be considered as a history of structure gradually hiding among walls.

Trains’ wheels-on-rail structure seems also follow this current. Internal gear mechanism took place of steam locomotive’s exposed valve motion. Wheels are hardly visible at today’s high-speed trains. And finally, invisible magnetism is taking place of wheels at magnetic levitation (linear motor) trains.

How about our model trains? Model train controlling system is considered as one of the structures of model trains. DCC eliminated a kind of skill and device, like gaps on tracks, needed in DC.

Scale or miniaturizing is considered as a structure of model trains. But, today, it is difficult to guess the scale of a model photographed and represented in a magazine or web at a glance, due to its fine details, decoration and photo techniques.

Material and/or method used for modeling can be recognized as another structure of model trains. Once, brass models were usually sold undecorated. The unpainted brass model represented the craftsman’s marks of skill. These marks are difficult to find on plastic models. The 3D printer doesn’t craft but prints out the model. Moreover, undecorated models are rare today. Decorations like painting, lettering, and weathering hide the structure.

The destiny of structure is that it may gradually be hidden if we approve of the history of the structure. Then, is the decoration such as painting, lettering, and weathering, also gradually being hidden? The decoration itself would not hide. But, I think its technique is also going to be hidden behind the 3D printing in the near future. If so, it will paradoxically demonstrate that the decoration is also a structure of model trains.

: wheels on rail. Naniwa, Osaka, Japan. 2002

: wheels on rail. Naniwa, Osaka, Japan. 20022014-02-14 09:00

コメント(2)

N scale Boxcar Ends 01 – Murphy Pressed Ends [Column_Parts & Materials]

: Orland Park, Il. Sep. 12, 2019

: Orland Park, Il. Sep. 12, 2019Interest for the accuracy of boxcar ends brought up in my mind while I was modeling the B&LE boxcar. I think the matching of sides and ends composes the character of a particular boxcar: details like rivets, ladders, and ribs contribute to it. Differences of ends are tiny in N scale, but not so tiny ignoring them. But we have few replacement parts in N scale. So, I researched my collections by scanning the models to find accurate car ends for the next work. Here are the results starting with Murphy:

Walter Patten Murphy(1873 - 1942) of Pressed Steel Mfg. Co. invented the sheet metal railway car end. The application was filed on Aug. 28, 1911, and was patented on Jul. 2, 1912 as US103157 A. USRA 50-ton boxcars with Murphy ends were first built in 1918. Companies controlled by Murphy were succeeded to Standard Railway Equipment Manufacturing Co. of Chicago, Il.

revised, Oct. 10, 2014

: Atlas USRA Double-Sheathed Boxcar

: Atlas USRA Double-Sheathed BoxcarThese 5/5/5 Murphy pressed steel ends are found on Atlas USRA Single and Double Sheathed Boxcars. Rivets connecting the three corrugated panels are represented. Also, are the poling pockets. Handbrake, brake platform, and tack board are separate parts.

: Atlas USRA Single Sheathed Boxcar (modified)

: Atlas USRA Single Sheathed Boxcar (modified)These 7/8 Murphy pressed steel ends are found on Atlas USRA Single and Double Sheathed Boxcars. Notice that the end door in the photo above is my modification. Rivets connecting the two corrugated panels are represented. Also are the poling pockets. Hand brake, brake platform and tack board (Both removed in the photo) are separate parts.

2014-06-27 09:00

コメント(0)

N scale Boxcar Ends 02 – Pullman-Standard Pressed Ends [Column_Parts & Materials]

: Ogden, UT. Sep. 10, 2014

: Ogden, UT. Sep. 10, 2014I researched my collections through scanning the models to find accurate car ends for the next work. Here are the Pullman pressed ends found in my collection:

Pullman-Standard Car Manufacturing Company was established in 1930 and based in Chicago.

Pullman introduced PS-1 boxcar with its original pressed rib ends in 1947. According to “The Model Railroader’s Guide to Freight Cars”, two corrugated panels were riveted together until the mid-1950s.

: Micro-Trains 40’ (top), 50’ (middle), and revised 50' (bottom) Standard Boxcar

: Micro-Trains 40’ (top), 50’ (middle), and revised 50' (bottom) Standard BoxcarThese Pullman-Standard 4/5 pressed rib ends are found on Micro-Trains series #020 to 024, #031 to 034, #036 to 038 and #073 to 077 Standard Boxcars. Rivets connecting the two corrugated panels are represented. They have Ajax pressed steel brake wheels. Latest cars have see-through roofwalk and metal brake platform.

: Athearn 50’ PS-1 Boxcar

: Athearn 50’ PS-1 BoxcarThese Pullman-Standard 4/5 pressed rib ends are found on Athearn 50’ PS-1 Single Door, Double Door and Plug Door Boxcars. They have standardized brake wheels. They also have straight retaining valve piping, contrary to MTL ends’ angled piping.

: Atlas Trainman 40’ PS-1 Boxcar

: Atlas Trainman 40’ PS-1 BoxcarThese Pullman-Standard 4/5 pressed rib ends are found on Atlas Trainman 40’ PS-1 and 40’ Plug Door Boxcars. They have standardized brake wheels.

: AHM 40’ Steel Combo Door Boxcar

: AHM 40’ Steel Combo Door BoxcarThis Pullman-Standard 4/5 pressed rib end is found on AHM 40’ Combo Door Boxcar. It has standardized brake wheel. Poling pocket is represented at the sill. According to Spookshow, this model dates to the early days of N scale (late 60's / early 70's).

: Atlas Master PS-1 40’ Boxcar

: Atlas Master PS-1 40’ BoxcarThis Pullman Standard 4/5 pressed rib end is found on Atlas master PS-1 40’ Boxcar. Miner, Universal and Ajax brake wheels, ladders, brake platform and tack boards are included as separate parts. Undecorated car has Pullman, 7 panel, 6 panel Superior and Youngstown doors along with it.

: True Line Trains 50’ Newsprint Boxcar

: True Line Trains 50’ Newsprint BoxcarThis Pullman-Standard (exactly, National Steel Car of Canada) 3/3/3 pressed rib end is found on True Line Trains 50’ Newsprint Boxcar. Weld beads between the three corrugated panels are represented. It has standardized brake wheel at lower position. End crossover walkway is molded on the body. Ladders are separate parts.

: Micro-Trains 40’ Hy-Cube Boxcar

: Micro-Trains 40’ Hy-Cube BoxcarThis Pullman-Standard 3/3/5 pressed rib end is found on Micro-Trains series #101 40’ Hy-Cube Boxcar. It has standardized brake wheel at lower position.

revised, Mar. 25, 2015

revised, Nov. 12, 2021

2014-07-04 09:00

コメント(0)

N scale Boxcar Ends 03 – Stanray Dreadnaught Ends [Column_Parts & Materials]

: Atlanta, IL. Sep. 12, 2019

: Atlanta, IL. Sep. 12, 2019I researched my collections by scanning the models to find accurate car ends for the next work. Here are the Stanray Dreadnaught ends found in my collection:

Standard Railway Equipment Manufacturing Co. was established and based in Chicago. Standard supplied car ends, roofs, hopper doors, and others. Their car ends are well known to us as the “Dreadnaught” ends. The company later abbreviated its name to Stanray Corporation.

According to “The Model Railroader’s Guide to Freight Cars”, Stanray’s “Dreadnaught” ends introduced in 1925 had a series of distinctive “darts”. In 1945, Stanray replaced the darts with long narrow corrugations as “improved Dreadnaught” ends. Additional thin corrugation at the top was added since 1948.

: InterMountain Railway 1937 AAR 40’ Boxcar

: InterMountain Railway 1937 AAR 40’ BoxcarThis Stanray 4/5 pressed Dreadnaught end is found on InterMountain Railway 1937 AAR 40’ Boxcar. Rivets connecting the two corrugated panels are represented. Also are the poling pockets. They have Ajax pressed steel brake wheels. Ladder, stirrup, tack board, hand brake piping and brake platform are separate parts.

: InterMountain Railway AAR 50’ Double (above) and Single (below) Door Boxcar

: InterMountain Railway AAR 50’ Double (above) and Single (below) Door BoxcarThese Stanray 5/5 pressed Dreadnaught ends are found on InterMountain Railway AAR 50’ Boxcars. Rivets connecting the two corrugated panels are represented. Also are the poling pockets. They have Ajax pressed steel brake wheels. Ladder, stirrup, tack board, hand brake piping and brake platform are separate parts. Difference between the two is the position of the tack board.

: Fox Valley Models Milwaukee Road 50’ Rib Side Boxcar

: Fox Valley Models Milwaukee Road 50’ Rib Side BoxcarThis Stanray 5/5 pressed Dreadnaught end is found on Fox Valley Models Milwaukee Road 50’ Rib Side Boxcar. Weld bead between the two corrugated panels is represented. Its brake wheel has five spokes in a spiral pattern; resembles Peacock, but in counterclockwise spire. Brake platform is an etched metal separate parts.

: Micro-Trains 50’ Auto Boxcar

: Micro-Trains 50’ Auto BoxcarThis Stanray 5/5 pressed Dreadnaught end is found on Micro-Trains 50’ Auto Boxcar. Rivets connecting the two corrugated panels are represented. Also are the poling pockets. “A” end has double hinged doors for auto service. It has Ajax pressed steel brake wheel.

: Micro-Trains Wagon Top Boxcar

: Micro-Trains Wagon Top BoxcarThis Stanray 4/5 pressed Dreadnaught end is found on Micro-Trains Wagon Top Boxcar. Rivets connecting the two corrugated panels are represented. Also are the poling pockets. It has Ajax pressed steel brake wheel.

: Atlas Trainman 50’ Double Door Boxcar

: Atlas Trainman 50’ Double Door BoxcarThis Stanray 5/5 pressed Dreadnaught end is found on Atlas Trainman 50’ Double Door Boxcar. Rivets connecting the two corrugated panels are represented. It has standardized brake wheel.

2014-07-11 09:00

コメント(0)

N scale Boxcar Ends 04 – Stanray Improved Dreadnaught Ends [Column_Parts & Materials]

: Gunnison, CO. Sep. 6, 2017

: Gunnison, CO. Sep. 6, 2017I researched my collections through scanning the models to find accurate car ends for the next work. Here are the Stanray Improved Dreadnaught ends found in my collection:

: InterMountain Railway Modified AAR 40’ Boxcar

: InterMountain Railway Modified AAR 40’ BoxcarThis Stanray 3/4 pressed improved Dreadnaught end with “rolling pin” shaped ribs is found on InterMountain Railway Modified AAR 40’ Boxcar. It has Ajax pressed steel brake wheel. Ladder, stirrup, tack board, hand brake piping and brake platform are separate parts.

: InterMountain Railway 12 Panel 40’ Boxcar

: InterMountain Railway 12 Panel 40’ BoxcarThis Stanray 3/4 pressed improved Dreadnaught end with “rolling pin” shaped ribs is found on InterMountain Railway 12 Panel 40’ Boxcar. It has standardized brake wheel. Ladder, stirrup, tack board, hand brake piping and brake platform are separate parts.

: Micro-Trains 51' 3¾ Rivet Side Mechanical Reefer

: Micro-Trains 51' 3¾ Rivet Side Mechanical ReeferThese Stanray 3/4 pressed improved Dreadnaught ends are found on Micro-Trains series #069 Rivet Side and #070 51' 3¾ Rib Side Mechanical Reefers. Rivets connecting the corrugated panels are represented. Also are the poling pockets. They have Ajax pressed steel brake wheels.

: Atlas 50’ Fruit Growers Express Boxcar

: Atlas 50’ Fruit Growers Express BoxcarThis Stanray 3/4 pressed improved Dreadnaught end is found on Atlas 50’ Fruit Growers Express Boxcar. Rivets connecting the two corrugated panels are represented. It has standardized brake wheel at lower position. End crossover walkway is a separate parts.

: Atlas Precision Design Rib Side Boxcar

: Atlas Precision Design Rib Side BoxcarThis Stanray 3/4 pressed improved Dreadnaught end is found on Atlas Precision Design Rib Side Boxcar. Rivets connecting the corrugated panels are represented. It has standardized brake wheel at lower position. Ladders, handrail, and end crossover walkway are separate parts.

: Athearn NACC 50’ Boxcar

: Athearn NACC 50’ BoxcarThis Stanray 3/4 pressed improved Dreadnaught end is found on Athearn NACC 50’ Boxcar. It has standardized brake wheel at lower position. End crossover walkway is molded on the body.

: ExactRail Gunderson 5200 Boxcar

: ExactRail Gunderson 5200 BoxcarThis Stanray 4/4 pressed improved Dreadnaught end is found on ExactRail Gunderson 5200 Boxcar. It has standardized brake wheel at lower position. End crossover walkway is molded on the body.

: Wheels of Time PC&F 50-ft 70ton Insulated Boxcar

: Wheels of Time PC&F 50-ft 70ton Insulated BoxcarThis Stanray 4/4 pressed improved Dreadnaught end is found on Wheels of Time PC&F 50-ft 70ton Insulated Boxcar. Rivets connecting the corrugated panels are represented. Also are the six vents. It has standardized brake wheel at lower position. End crossover walkway is a separate parts.

: ExactRail PC&F 6033 Cubic foot Hy-Cube Boxcar

: ExactRail PC&F 6033 Cubic foot Hy-Cube BoxcarThis Stanray 3/3/3 pressed improved Dreadnaught end is found on ExactRail PC&F 6033 Cubic foot Hy-Cube Boxcar. Weld beads between the three corrugated panels are represented. It has standardized brake wheel at lower position.

2014-07-18 09:00

コメント(0)

N scale Boxcar Ends 05 – Non-Terminating Ends [Column_Parts & Materials]

: Fairbanks, AK, Feb. 15, 2012

: Fairbanks, AK, Feb. 15, 2012I researched my collections through scanning the models to find accurate car ends for the next work. Here are the non-terminating ends found in my collection. I could only identify Pullman as the manufacturer: they are so alike. Here are the Pullman and the others:

: InterMountain Railway PS 5277 Cubic Foot Boxcar

: InterMountain Railway PS 5277 Cubic Foot BoxcarThis Pullman-Standard 5/5 non-terminating corrugated end is found on InterMountain Railway PS 5277 Cubic Foot Boxcar. It has standardized brake wheel at lower position. Ladders, handrail and end crossover walkway are separate parts.

: Micro-Trains 50’ Rib Side Box Car

: Micro-Trains 50’ Rib Side Box CarThese 6 rib non-terminating corrugated ends are found on Micro-Trains series #025 to 027 and #030 50’ Rib Side Box Cars. This sample has Ajax brake wheel at lower position.

: Athearn 50’ FMC Boxcar

: Athearn 50’ FMC BoxcarThese 6 rib non-terminating corrugated ends are found on Athearn 50’ FMC Single, Double, Combo and Plug Door Boxcars. They have standardized brake wheel at lower position.

: Fox Valley Models FMC 5283 Cubic foot Double Door Boxcar

: Fox Valley Models FMC 5283 Cubic foot Double Door BoxcarThis 6 rib non-terminating corrugated end is found on Fox Valley Models FMC 5283 Cubic foot Double Door Boxcar. It has standardized brake wheel at lower position. End crossover walkway is a separate parts.

: Trainworx Rio Grande FMC Woodpacker Boxcar

: Trainworx Rio Grande FMC Woodpacker BoxcarThis 6 rib non-terminating corrugated end is found on Trainworx Rio Grande FMC Woodpacker Boxcar. It has standardized brake wheel at lower position. End crossover walkway is a separate parts.

2014-07-25 09:00

コメント(0)

Watching the Rivets – Variety of Side Seams [Column_Parts & Materials]

I recently had some questions about seams on boxcar sides. But I’m not familiar with the construction. Accordingly, I decided to scatter my detail photos which might help someone find out the answer.

Panel Usage – Vertical or Horizontal

The material of steel car sides seems to be delivered in a coil. But the possible widest steel panel cut from the coil is not wide enough to cover the side of a car by itself. Therefore, numbers of panels are used to cover the side of a car. Here, the seams arise companied with rivets or weld beads. If you apply the panels horizontally, the seams also run horizontally, and if you apply the panels vertically, the seams also appear vertically.

UP caboose #25432 shown below shows the vertical seams, and C&EI caboose #unknown also shown below shows horizontal seam. WCLX reefer #2571 shown at the bottom also has a horizontal seam.

: UP caboose #25432

: UP caboose #25432

: C&EI caboose #unknown

: C&EI caboose #unknown

Panel Orders

Car sides are usually designed symmetrically. Before the introduction of non-terminating ends, the car ends used to wrap the edge of side panels. Accordingly, the order starting at the opening in the middle of the car side toward both ends seems the norm at side panels: the panels at both ends are the last to fit. For example, IC boxcar #35827 shown below shows five panels lined in this order.

But there are the exceptions; at SFRD #15187 also shown below, the panel right next to the end panel is the last to fit.

: IC boxcar #35827

: IC boxcar #35827

: ATSF reefer SFRD #15187

: ATSF reefer SFRD #15187

Joint Constructions – Lap or Batten

Steel panels are fitted to the car body by means of rivet or weld construction. To make the seam watertight in rivet construction, panels are lapped or battened. UP caboose #25432 shown previously shows the lap joints, and C&EI caboose #unknown also shown previously shows the batten joint.

Lapping the panel causes a certain gap according to its own thickness. But the gap seems not such a big issue at boxcars. Accordingly, simply leaving the gap undone is the norm. IC boxcar #35827 shown above or UP MW Materials Car #910261 shown below shows the simple construction.

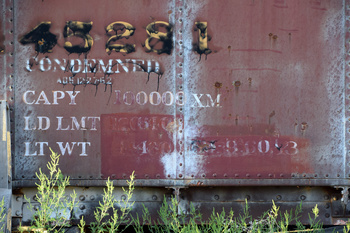

Some car builders minded the gap. To resolve the gap, they bent one side of the panel to make room for the next panel. The steel plate used in this way of construction may have been thicker than it of simple construction represented above. ATSF boxcar #145281 and SFRB #5358 shown below show the bent panel joints.

: UP MW Materials Car #910261

: UP MW Materials Car #910261

: ATSF boxcar #145281

: ATSF boxcar #145281

Rivets – Sizes, Pitches, Gauges and Patterns

The strength of a rivet itself depends on the diameter of its shank. The diameter of a rivet head is directly proportional to the diameter of the shank. Accordingly, the larger rivet head indicates the more stressed part. Larger rivet at the corner of the panel of ATSF boxcar #145281 shown above is the example.

To avoid edge cracking, rivets must keep minimum edge distance. But in my photos shown here, the edge distances seem not secured at the upper panel; distances are maybe secured at the lower panel. Therefore, the line of rivets is maybe staggered in the width of the bend at ATSF boxcar #145281 shown above or SFRB #5358 shown below.

The number of the row of rivets depends on the shape of the posts used. Posts are located behind the panel joints. Z-shaped posts allow a single row of rivets, while hat-shaped posts allow a double row of rivets.

The double row of rivets makes several patterns: chain row rivets, staggered row rivets, and zigzag row rivets. Patterns seem to depend on their substrates and needed strength.

C&EI caboose #unknown shown at the top shows chain row rivets; maybe upper row fits upper panel and lower row fits lower panel under the batten. ATSF Bx-88 class boxcar shown below barely shows the sign of the flange of the post under the staggered row rivets at the bottom. WCLX reefer #2571 shown below shows zigzag row rivets.

: ATSF reefer SFRB #5358

: ATSF reefer SFRB #5358

: ATSF Bx-88 class boxcar

: ATSF Bx-88 class boxcar

: WCLX reefer #2571

: WCLX reefer #2571

Panel Usage – Vertical or Horizontal

The material of steel car sides seems to be delivered in a coil. But the possible widest steel panel cut from the coil is not wide enough to cover the side of a car by itself. Therefore, numbers of panels are used to cover the side of a car. Here, the seams arise companied with rivets or weld beads. If you apply the panels horizontally, the seams also run horizontally, and if you apply the panels vertically, the seams also appear vertically.

UP caboose #25432 shown below shows the vertical seams, and C&EI caboose #unknown also shown below shows horizontal seam. WCLX reefer #2571 shown at the bottom also has a horizontal seam.

: UP caboose #25432

: UP caboose #25432 : C&EI caboose #unknown

: C&EI caboose #unknownPanel Orders

Car sides are usually designed symmetrically. Before the introduction of non-terminating ends, the car ends used to wrap the edge of side panels. Accordingly, the order starting at the opening in the middle of the car side toward both ends seems the norm at side panels: the panels at both ends are the last to fit. For example, IC boxcar #35827 shown below shows five panels lined in this order.

But there are the exceptions; at SFRD #15187 also shown below, the panel right next to the end panel is the last to fit.

: IC boxcar #35827

: IC boxcar #35827 : ATSF reefer SFRD #15187

: ATSF reefer SFRD #15187Joint Constructions – Lap or Batten

Steel panels are fitted to the car body by means of rivet or weld construction. To make the seam watertight in rivet construction, panels are lapped or battened. UP caboose #25432 shown previously shows the lap joints, and C&EI caboose #unknown also shown previously shows the batten joint.

Lapping the panel causes a certain gap according to its own thickness. But the gap seems not such a big issue at boxcars. Accordingly, simply leaving the gap undone is the norm. IC boxcar #35827 shown above or UP MW Materials Car #910261 shown below shows the simple construction.

Some car builders minded the gap. To resolve the gap, they bent one side of the panel to make room for the next panel. The steel plate used in this way of construction may have been thicker than it of simple construction represented above. ATSF boxcar #145281 and SFRB #5358 shown below show the bent panel joints.

: ATSF boxcar #145281

: ATSF boxcar #145281Rivets – Sizes, Pitches, Gauges and Patterns

The strength of a rivet itself depends on the diameter of its shank. The diameter of a rivet head is directly proportional to the diameter of the shank. Accordingly, the larger rivet head indicates the more stressed part. Larger rivet at the corner of the panel of ATSF boxcar #145281 shown above is the example.

To avoid edge cracking, rivets must keep minimum edge distance. But in my photos shown here, the edge distances seem not secured at the upper panel; distances are maybe secured at the lower panel. Therefore, the line of rivets is maybe staggered in the width of the bend at ATSF boxcar #145281 shown above or SFRB #5358 shown below.

The number of the row of rivets depends on the shape of the posts used. Posts are located behind the panel joints. Z-shaped posts allow a single row of rivets, while hat-shaped posts allow a double row of rivets.

The double row of rivets makes several patterns: chain row rivets, staggered row rivets, and zigzag row rivets. Patterns seem to depend on their substrates and needed strength.

C&EI caboose #unknown shown at the top shows chain row rivets; maybe upper row fits upper panel and lower row fits lower panel under the batten. ATSF Bx-88 class boxcar shown below barely shows the sign of the flange of the post under the staggered row rivets at the bottom. WCLX reefer #2571 shown below shows zigzag row rivets.

: ATSF reefer SFRB #5358

: ATSF reefer SFRB #5358 : ATSF Bx-88 class boxcar

: ATSF Bx-88 class boxcar : WCLX reefer #2571

: WCLX reefer #25712016-12-16 09:00

コメント(2)

Improvements in the Past Decade [Column_Parts & Materials]

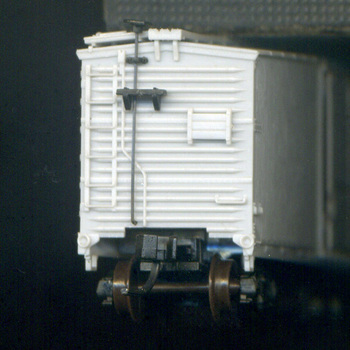

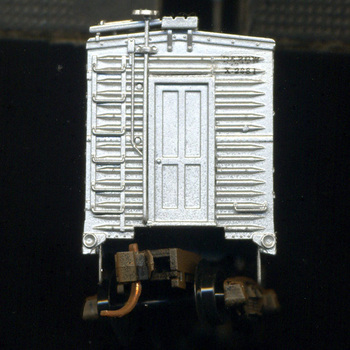

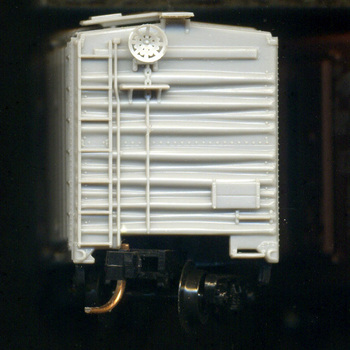

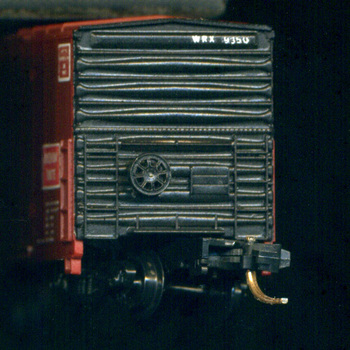

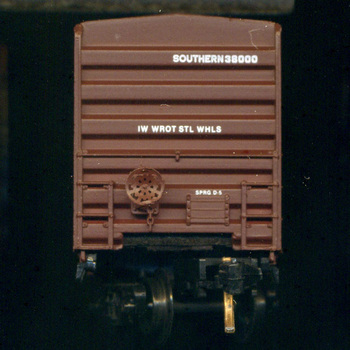

: MTL products with the new frame (left) and the old frame (right)

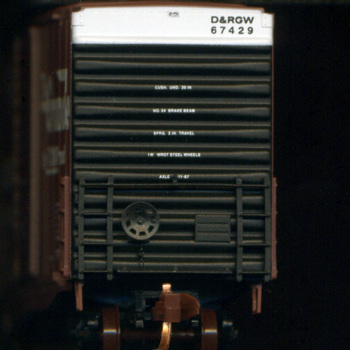

: MTL products with the new frame (left) and the old frame (right)The lowering of the underframe achieved by Micro-Trains Line is thought to be one of the most significant product improvements made by N scale model manufacturers in the past decade.

High-riding body and truck-mounted couplers featured on MTL N scale boxcars were long discussed among serious modelers. MTL finally introduced its #180 to #182 series boxcars in July 2017. But MTL only boasted of its etched metal brake platforms at that time. At last, in January 2019, MTL announced its “New Lowered Underframe w/Body-Mount Couplers” resolving the discussion.

The improvement is obvious in my photos represented here. CB&Q 23271 has the new underframe, and D&H 25019 has the traditional underframe. Both have genuine trucks. Compared to the old product, the floor of the new product is definitely lowered. But the extreme height seems the same between the two. Accordingly, the side of the new body looks much “great”.

How did they do that? Photos below clearly show the solution: simply lowering the height of the bolster and thinning the floor to avoid contact with the wheels. Thus, the new underframe also fits the old body. But the traditional MTL trucks with couplers won’t fit the new underframe: the coupler box conflicts with the frame. So, if you decided to swap your old underframe, you also have to swap trucks and couplers. Moreover, if you do so, the car will become a "little boy".

As I mentioned above, the couplers of MTL #180 to #182 series boxcars are Body-mounted. The body-mount longer shank couplers are adopted to these cars, maybe due to negotiating tight curves and turnouts. But, it causes more distance coupling than traditional coupling made by truck-mount shorter shank couplers.

Then, what is the purpose of the body-mounting of the couplers in N scale? One says it's much smoother when backing a train through the turnouts. One says it’s more realistic. These don’t affect me for the time being: I don’t switch, I don’t need details like train lines or cut levers on my boxcars, and I prefer space-efficient close coupling.

The improvement done by MTL shows continuity: replaceable but even overall. Though, I won’t swap my old underframes concerning the sense of unity of the extreme height. The only anxiety I have is the mixture use of truck-mount couplers and body-mount couplers.

2023-01-13 09:00

コメント(0)